We can offer professional design & manufacture for containers, sealing films, packing machines, and full production lines.

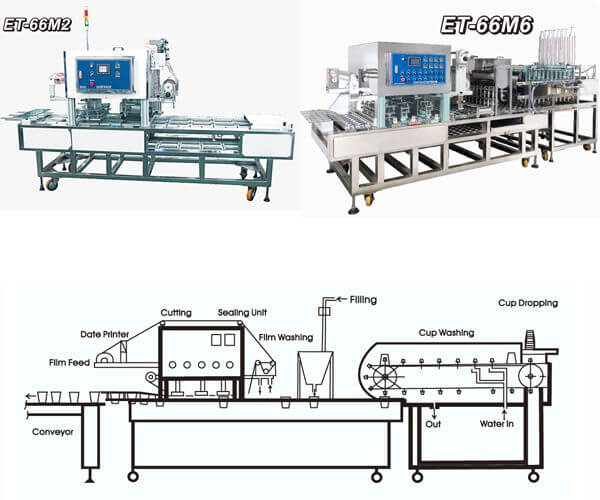

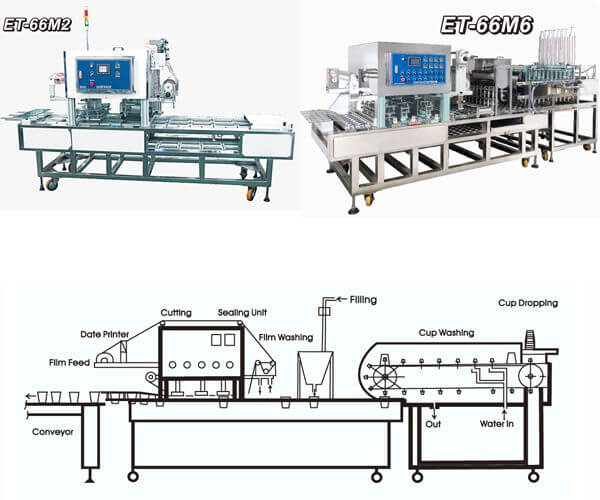

The ET-66 series of the Automatic Continuous Container Filling and Sealing Machine is a top-of-the-line solution for packaging and sealing containers. With its professional design and high-quality construction, you can trust this machine to deliver reliable and efficient performance for your business. At the heart of the ET-66 is its advanced technology, including a PLC system with an Index Gear Conveyor, Inverter Speed Control, and Touch Screen Operation. The stainless steel frame and anodized aluminum construction ensure durability and longevity, while the three available models for Film Feeding: Sensor, Encoder, and Timer provide versatile options for your needs. Whether you're using colorful or blank film, you'll be able to produce seamless, high-quality seals every time. With two sets of separate sealers and one set of cutters, this machine is faster and more efficient than ever. Whether you're packaging beverages, snacks, processed agricultural products, or any other type of food, the ET-66 can handle it all. The sealable material options are wide-ranging, including PP, PE, PS, PET, HDPE, EPS, PSP, aluminum foil, and paper boxes.